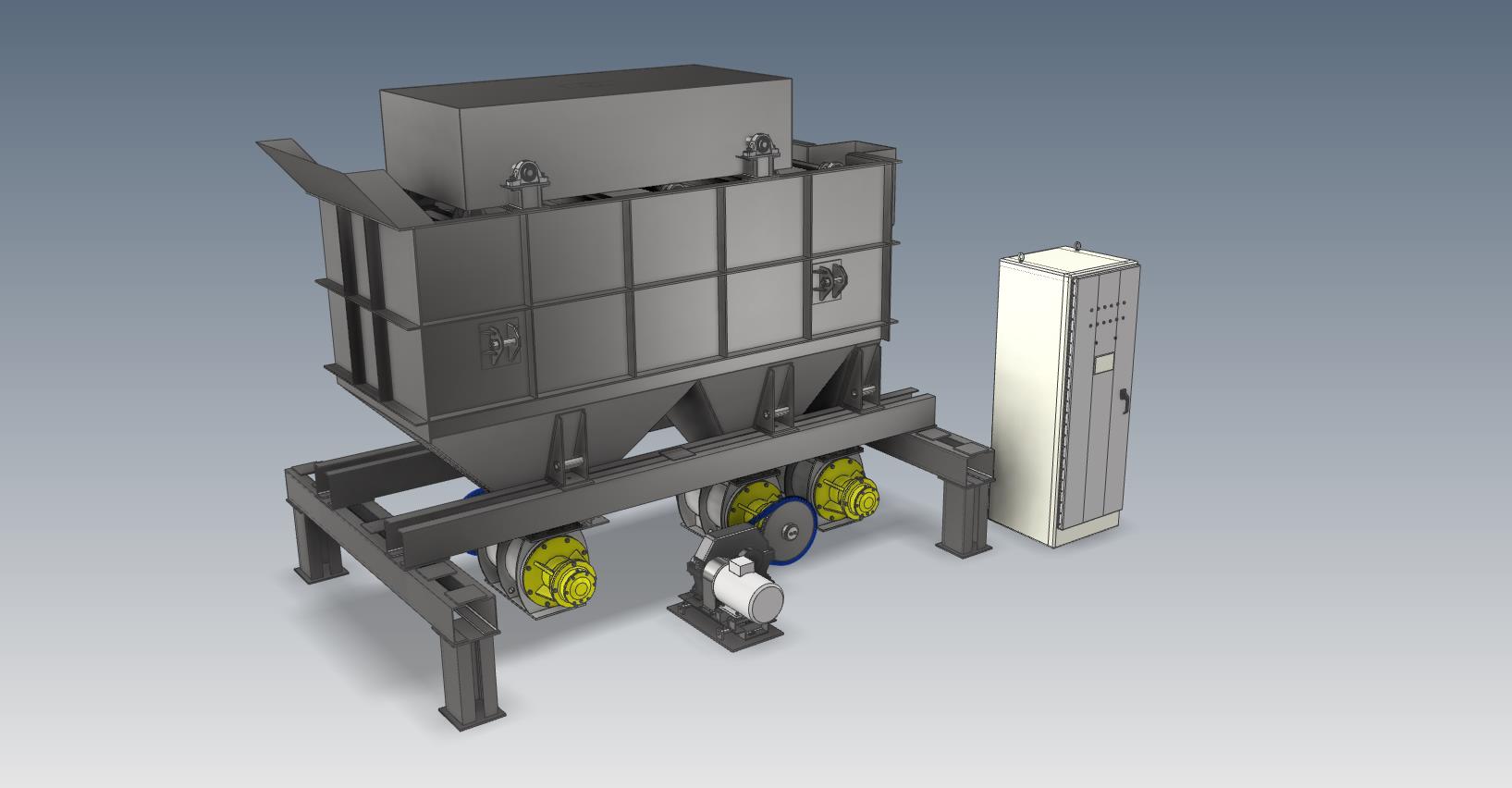

In 2020, NPK Gravicon developed an innovative GRAVIPOD-EVO jigging machine with an electronically driven movable sieve based on modern technologies. Thanks to the achieved dynamics of the movement of the sieve, it was possible to double the productivity from 1m2 of the working sieve while improving the quality performance indicators. Other indicators of modular complexes based on the new OM are also revolutionary:

- air consumption - 0 m3/h;

- electricity consumption - less than 0.8 kWh per 1 ton of source (completely complex including water supply pumps, slurry pumps, conveyors and dewatering screens). Such low power consumption simplifies the task of power supply of the complex, especially in remote areas - a small 50 kW diesel generator provides electricity to the processing complex for 50 tons per hour (namely, the processing complex, without a crushing section);

- fully complete modular delivery with cables laid along the structures and installed elements of the control system;

- installation time at the facility is reduced from 1-3 months to 5-7 days;

- support foundations are not needed - any even prepared surface is sufficient;

- reduction of recycled water tanks by 5-7 times compared to traditional solutions and 1.5-2 times compared to previous models of machines with a moving sieve. Often it is the presence of water that is the stumbling block when using jigging technology. New technology reduces this problem to a minimum. So, for a complex for 50 tons per hour on the basis of jigging machines with a dynamic movable sieve, three recycled water tanks of 250 m3 each are required. The classical technology of stationary concentration plants required at least 5000-10000 m3;

- the above two points simplify or even eliminate the need to obtain permits for construction work and commissioning;

- full modularity of the solution - the increase in productivity occurs in parallel with the increase in enrichment cells without losing investment in already purchased equipment. Which is useful with limited resources at the project launch stage. As the development progresses, it is possible to develop productivity without stopping the running production.

The limitations of the new technology are the size of the enriched material up to 50 mm, which covers 95% of the situations of enrichment of materials by hydraulic jigging: most coals, manganese and iron ores, man-made slag dumps, diamonds, etc. are enriched to exactly this size. The remaining 5% of cases, when it is necessary to enrich large classes of 50-150 mm, are covered by the solutions of the company NPK Gravikon based on air-pulsation elevatorless jigging machines.

Moving sieve jigging machines are modern, highly efficient enrichment equipment that allows obtaining high quality product separation with a significant reduction in operating and energy costs. It is possible to use jigging machines with a movable sieve as part of the GRAVICOM modular processing complexes.

One of the main differences of GRAVIPOD jigging machines is the presence of elevatorless unloading. This solution eliminates the three elevators required for a two-section jigging machine and replaces them with dewatering screens. This solution allows to significantly reduce capital costs, reduce the weight and dimensions of the enrichment module both in width and height, significantly reduce operating costs both in time and in amount (replacement of bucket belts and especially guides has always been criticized by technical services for the high cost and complexity of implementation), and also provides a closed water-slurry scheme.

Moving sieve jigging machines are modern, highly efficient enrichment equipment that allows obtaining high quality product separation with a significant reduction in operating and energy costs. It is possible to use jigging machines with a movable sieve as part of the GRAVICOM modular processing complexes.